Standard twisted wires form the basis of braces, applying constant pressure as their material seeks to return to original shape. Beginning larger, they progressively downsize to alleviate discomfort while continuing treatment.

Coordinated archwires consider both jaws, controlling them simultaneously through specially programmed curves and sequences. Their advanced design precisely maneuvers teeth in harmony with facial growth.

Esthetic braces use transparent or tooth-colored materials for a subtle look. Made of plastics or ceramics instead of metal, they appeal to patients seeking discreet treatment while still achieving orthodontic correction through customized control of individual teeth.

Key Takeaways

- Standard wires apply a constant, uniform force but come in different thicknesses to accommodate treatment stage and comfort levels.

- Coordinated archwires piloted sophisticated smile designs through pre-programmed sequences that govern both dental arches as a matched set.

- Esthetic options allow orthodontics with minimal visibility using virtually invisible materials like plastics and ceramics instead of traditional metal wires.

- Some wires contain memory metals like nickel-titanium that recall their factory shape for superlight continuous pressure over the course of treatment. Don’t miss to read out this topic Braces Wire Size Chart.

- Cutting edge orthodontics now employ customized digital designs and 3D printing techniques to produce perfectly tailored archwires fitted to individual patients’ unique teeth and jaw structures.

Overview Of Different Types Of Wires For Braces

Braces rely on specialized wires to effectively move teeth into the desired positions. Standard twisted wires apply a sustained force, while memory metals shape shift to provide light continual pressure. Coordinated archwires choreograph both dental arches as a matched set.

Esthetic wires now come made of clear or tooth-colored materials for discreet treatment. Cutting-edge customized digital designs and 3D printing fabricate precisely tailored wires. Through their varied techniques, wires are the engines that drive braces to flawless orthodontic outcomes.

Step By Step Guide To Different Types Of Wires For Braces

- An assessment determines malocclusion severity and customized treatment plan. This dictates initial wire thickness for balanced forces aiding early alignment.

- Coordinated archwires ensure arches move in harmonized symmetry. Their curvatures choreograph dental grouping like musical staves directing flawless formation.

- Non-metallic esthetic wires provide optical stealth for subtle confidence. Whether transparent plastics or ceramic look-alikes, personalized designs discreetly chauffeur smiles to radiant destinies undisguised.

Different Braces Wire Stages

The orthodontist begins with simple plastic aligners to straighten front teeth on the top jaw. Next, thin threaded wires are added behind the plastic to slowly put pressure on molars. Larger diameter wires are installed as gaps close, shaping the dental arch into place.

Colored ligatures are now used to tighten wires quarterly, conforming the bite precisely. Gradually, wires become smaller again until discreet clear brackets can remove the final refinements. With braces complete, a bright smile shows teeth perfectly positioned.

Orthodontic Wires And Their Uses

Different gauges of orthodontic wire help realign teeth in stages. Thin starter wires place initial pressure as plastic aligners organize the front. Medium wires work molars into place with steady force over months.

Thicker stabilization wires lock improvements in while slight bends guide lateral movements. Finishing wires make tiny corrections, carefully twisting under blue ligatures. Once straight and aligned, polished teeth shine through with the customized curve of each customized archwire.

Braces Wire Thickness Chart

A variety of wire thicknesses provide customized tooth movement during orthodontic treatment. Beginning wires measure 0.012 inches to gently shift front teeth into place. As gaps diminish, 0.016 inch wires harness fuller force to exert pressure on molars. Once bite registration begins, 0.018 or 0.020 inch wires firmly hold new positions in transition.

Final shaping utilizes 0.016 or 0.014 inch wires for their pliable precision. Through coordinated tension over timed stages, the tailored thickness chart brings each customized arch into focused function and form.

Braces Wire Size 16

As teeth begin finding their final positions, size 16 wires join the process. Their sturdy 0.016 inch thickness backs subtle movements guided by expert hands. Firm yet pliable, each customized bend directs roots and contacts into the register.

Size 16s steady pressure shapes upper and lower curves in coordinated arches. Through small half-turn adjustments, they refine jaws into balanced occlusion. With borders set, smiles now emerge with natural 16-wire definition.

Different Types Of Archwires For Braces

A variety of archwires shepherd teeth into alignment. Beta titanium wires start gentle progression. Copper Ni-Ti takes the lead with its memory-shaped ability. Stainless steel lends durability during bite adjustments. Spring-tempered wires ensure stable positioning.

A final aesthetic wire of esthetic poly-diamond readies smiles for polishing. Each specialized material contributes its force fine-tuned by the board certified orthodontist. Aesthetic polymers discretely hold teeth en route to imperceptible ceramics.

What Is The Thickest Wire For Braces

For stabilizing severe malocclusions with strong resistance, orthodontists turn to the heaviest wire in their toolkit. Measuring 0.021 or 0.022 inches in diameter, stainless steel offers unparalleled sturdiness for stubborn teeth or late-stage adjustments.

With its rugged rigidity yet supple flexibility, this stocky strand secures even dramatically drifting positions in their altered arches. Through precise bending and torquing, it bolsters compromised cases towards the finishing line. Now each tooth finds an anchor for the final homestretch’s refined calibrations.

Stainless Steel Braces Wire

The rugged material favors its name – stainless steel resiliently braces recalcitrant teeth on their quest for alignment. Where polymer pullers prove too pliant, and nickels too delicate, stainless steps firmly in.

Its steadfast gauges, wrought in varied widths, provide anchor for substantial shifting or stubborn bites. Through torque and tactful twisting, trained hands shape steel’s stable structure to customized molds. There, guided into purpose, an enduring finish awaits with new grins in resilient realignments.

Taking A Closer Look At Braces The Arch Wire

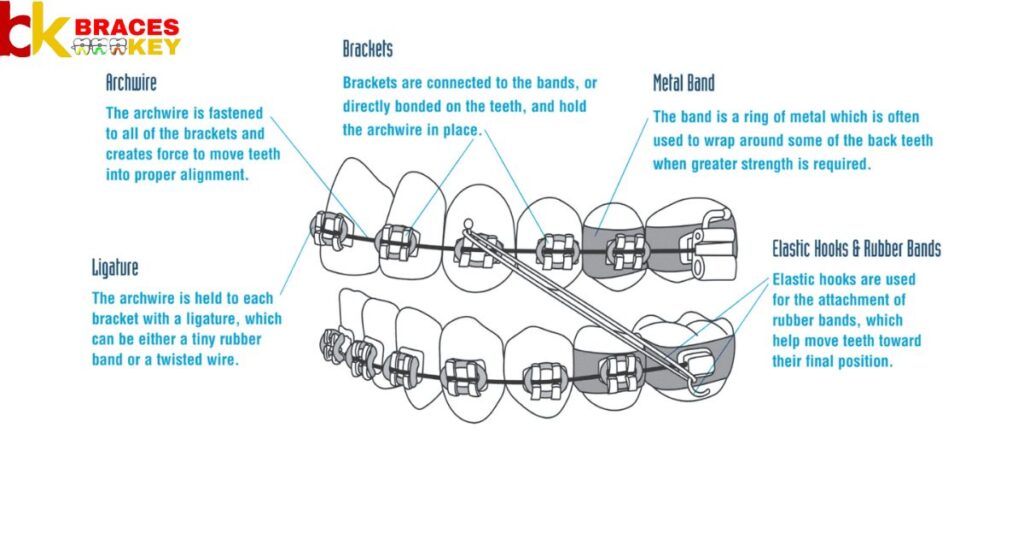

Threading through each bracket, the archwire forms orthodontics’ axis, transmitting precise forces through its curves and contours. Subjected to pressure yet pliable by design, this pivotal piece maneuvers teeth into their destined destinations.

Bent and bound in careful calibrations, the slender strand shepherds smiles towards straightened shores through subtle movements over months. Anchoring the smile makeover from start to shining finish, the archwire’s guidance gleams as brightening grins come into focus.

Types Of Braces Wires For Orthodontic Treatment

A calibrated collection of conductors calibrates the smile redirection. Beta titanium trains beginner teeth with gentle encouragement. Shape-shifting nickel alloys nudge nascent positions toward finer form.

Stainless steel’s reliable rigidity bolsters challenging cases over the lengthy haul. Clear polyurethane performers polish problematic presence with discretion. Each customized conductor calibrates correction, guiding teeth from where they have been toward where they will.

How Many Wires Do You Need For Braces?

While individual orthodontic journeys vary greatly, a typical braces treatment requires around a dozen archwires to progressively propel teeth into their perfect positions. Starter strands softly initiate shifts as lighter wires follow to fine tune alignments.

Medium gauges methodically manipulate misalignments while sturdier versions lock improvements in place. Final filaments delicately detail smiles until satisfactory straightness signifies success and wires are no more necessary thanks to the team that guided them.

Archwires In Spring

As buds burst forth on branches once barren, so too teeth thrill at spring’s spark within metal mouth molds. Gentle archwires like willow wisps whisper of warmer months to come, coaxing clenchers to calibrate curves with each coastal change.

Seasoned aligners sense shifting’s sweet seasons, seasonal sequences settling smirks just so. Now new grins greet hotter suns, by guides of gradually strengthening stainless spring. Spring’s vibrance energizes aligners and alignees alike to march teeth into their destined destinations.

FAQ’s

What Wire Is The Strongest For Braces?

Stainless steel braces wire has the most strength and durability to shift even stubborn teeth into their rightful places. Its stay power tolerates the toughest transformations.

What Do Thicker Wires Do For Braces?

Thicker wires lend more rigidity for proper biting and stability as teeth settle into final positions, ensuring solid foundations for smiles take permanent shape.

What Is The Special Wire For Braces?

Nickel titanium archwires are shape memory marvels, adjusting teeth with superhuman precision through memory metal’s ability to return to predetermined forms.

What Is The Last Wire For Braces?

Finishing wires ensure perfection, subtlety swaying teeth into congruent conformity before retention starts the smile’s reign without restraints.

Conclusion

From beginning to end, segmented archwires in varied widths and styles safely and smartly shift teeth towards their destinations. Each customized cable takes advantage of distinct properties – be it flexibility, strength or discretion, to progressively propel smiles to completion, Different Types Of Wires For Braces.

Whether Beta titanium takes tentative first steps or Teflon coated wires provide the polished finish, calibrated conductors collaborate articulately to redirect bites universally beautifully.